This content was published: February 17, 2013. Phone numbers, email addresses, and other information may have changed.

Bioscience industry builds a course’s DNA at PCC

Photos and Story by James Hill

As the overhead projector heats up, the lights are dimmed and the agenda sheets are handed out, people gather around the conference table to hash out details on such things like “product control” or “coordinated quality teamwork.” But the stars of this show are the strawberries.

Industry experts from companies like Welch Allyn, HemCon, AeroTek, Commissioning Agents, Inc., Oligos Etc., and HydraDx have gathered on a Thursday winter afternoon at Aerotek Staffing in Tigard to finish crafting the curriculum for a new applied quality practice course in Portland Community College’s Bioscience Technology Program.

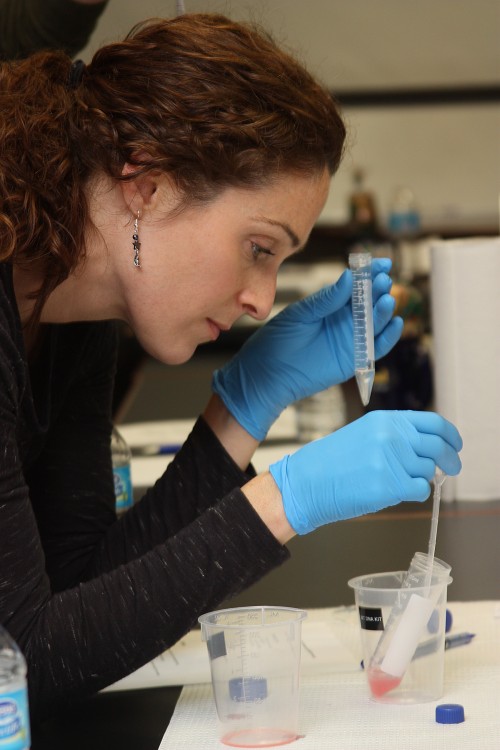

Naomi Allan of Welch Allyn extracts DNA from a strawberry during an advisory group meeting for the Bioscience Technology Program. The test helps the industry reps to see if it will work for students in a key class.

It is a Career Technical Education program based at the Rock Creek Campus (17705 N.W. Springville Road) and is part of PCC’s emphasis to bolster the number of students in STEM disciplines.

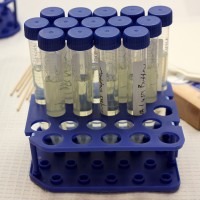

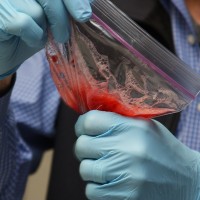

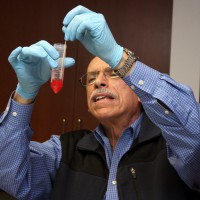

The eight-member advisory sub-committee uses a variety of tools – beakers, test tubes, filters and bottles of clear alcohol – to perform a test they created for the class. They will isolate and extract DNA from the strawberries to mimic the development process of a drug or a medical device. These experts designed the test kit to be complicated enough that it will force students to produce paperwork on the testing process, but simple enough that it can all be done in a few hours – perfect for a class environment.

“The committee members have never gone into a lab to experience the use of this kit,” said Josephine Pino, chair of the Bioscience Technology Program. “They wanted to see what it was like because the students will learn the same way.”

The sub-committee is part of a larger advisory board representing the bioscience industry, including biopharma giant Genentech. Their overall role is to advise the program on what is needed for the workforce, build awareness and partnerships, recruit potential students, provide worksites for cooperative education and periodically review the program’s mission statement.

“And they guide us through curricular changes to meet industry needs of Oregon,” added Pino. “Oregon has a unique environment for workforce needs. We lean on them very heavily to help us match curriculum to what is needed out there.”

Bioscience technology is a growing field that involves manufacturing of medical devices and the development of new bioscience procedures. From pharmaceutical drugs to pacemakers, genetically engineered plants to gene therapy, bioscience technology can be applied to a range of areas. Biotechnicians work in research, manufacturing and quality control, in analytical labs and in the field. The Bioscience Technology Program, one of only a handful of stand-alone programs in the country as many schools integrate the same curriculum into larger divisions, offers students an associate’s of applied science degree in Bioscience Technology, a Biotechnician Certificate, or transfer credits toward four-year schools.

Cheryl Bondurant works as Director of Quality for HemCon Medical Technologies, Inc., (located in Southwest Portland) and is on the curriculum sub-committee. As an instructor of Quality Systems and Applied Quality Practices for the Bioscience Technology Program her main goal is to ensure that students receive the skills they will need to excel in the field and ease training costs for companies.

“In general, all biotech companies, whether medical device, drug, or biologic, will benefit from the applied quality systems practices these students have learned,” Bondurant said. “As a result, companies will not have to invest in as much training.”

The curriculum sub-committee has met for the past nine months, donating more than 200 volunteer hours to the cause. The class they are creating guides students through the formation of little companies, the design and planning process of how their product is made, the production of documentation, and how to maintain the quality of the end product.

“Because manufacturing errors can be dangerous, having this skill makes them job ready,” Pino said. “Industry board members are very excited about this. Many said they learned at work, or from expensive courses, and had no opportunity at university or school. So they are excited to provide this opportunity to people getting into the industry.”

As the sub-committee performs its strawberry DNA test, there’s a problem. Bioscience Technology instructor Trish Willy calls for them to grab a test tube. Some in the group reach for the large test tubes while others go for smaller ones. This is a problem that they discover – the size of the tube must be spelled out. A stumbling block they would never have foreseen without trying out the test.

“We all learn through experience,” added Bondurant. “When a student performs a hands-on exercise they are experiencing what they will encounter on the job.”

The Strawberry DNA Test

I had no idea there was such a program at PCC. I have a background in chemistry and computer hardware R&D and I have been thinking about going into Biomedical Engineering but now my interest has been piqued by this article and I would like to know more about the program and opportunities in the Bioscience arena.

@Anthony That’s great. Here’s the contact info for the program….971-722-7257 or 971-722-7282 | josephine.pino@pcc.edu

My undergraduate degree is business from BYU and comtemplating taknig the cerificate course in accounting @UWA to pursue my CPA and now this course and the demand…interesting

[…] To read more about the role business plays in college curriculum, visit: http://news.pcc.edu/2013/02/bioscience-technology […]

[…] Bioscience industry builds a course’s DNA at PCC (1,202) […]